Because of its unique electrical properties, mechanical properties, thermal properties, optical properties, and high specific surface area, graphene has received great attention in the fields of chemistry, physics, materials, energy, and the environment in recent years. It has a broad application prospect and is recognized as the 21st century “Future materials” and “revolutionary materials.” Specifically in five application areas: First, energy storage. Graphene can be used to make supercapacitors, super lithium batteries, and the like. The second is the field of optoelectronic devices. Graphene can be used to make solar cells, transistors, computer chips, touch screens, and electronic paper. The third is the field of materials. Graphene can be used as a new additive for the manufacture of new coatings and antistatic materials. Fourth, the field of biomedicine. Graphene has good barrier properties and biocompatibility, and can be used in drug carriers, biological diagnostics, fluorescence imaging, and biological monitoring. Fifth is the field of heat dissipation. Graphene heat-dissipating films can be widely used in ultra-thin and high-power electronic products, such as smartphones, IPAD computers, semiconductor lighting, and LCD TVs that are currently selling worldwide. The Chinese Academy of Sciences expects that by 2024, graphene devices are expected to replace complementary metal oxide semiconductor (CMOS) devices and be used in research fields such as nanoelectronic devices, photoelectrochemical cells, and ultralight aircraft materials. At present, the global electronics industry alone consumes about 2,500 tons of semiconductor crystalline silicon every year. The market price of pure graphene is about 1,000 yuan / g. If it can replace 10% of the crystalline silicon market share, it can get 500 billion yuan. The above economic benefits; the global demand for anode materials is more than 25,000 tons each year, and has maintained a growth of more than 20%. If graphene can obtain 10% of the lithium ion battery market share as anode materials, it can obtain 2,500 tons. Market size. It can be seen that graphene has a wide application space and huge economic benefits.

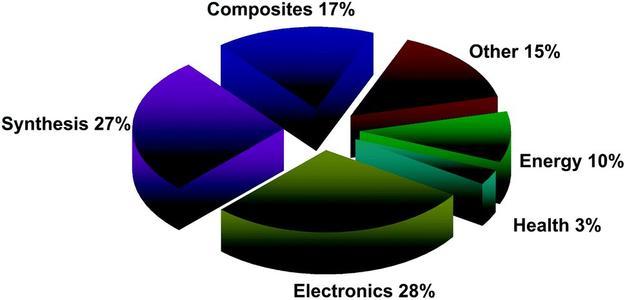

It is against this background that the current research on the application of graphene technology at home and abroad is in full swing, and the specific applications are as follows:

2.1 Graphene lithium ion battery

Lithium-ion batteries have the advantages of large capacity, long cycle life, and no memory. At present, they have become the battery of choice for global consumer electronics and the mainstream battery of new energy vehicles. High energy density and fast charging are an inevitable trend in the development of lithium battery products. Adding a conductive agent to the positive electrode material is an effective way to improve the performance of lithium batteries. , Increase the lithium ion de-intercalation and embedding speed, significantly improve the battery rate charge and discharge performance, and improve the fast charging performance of electric vehicles.

So-called graphene batteries are not made of graphene materials, but

The pole uses a graphene material. Graphene electrodes can theoretically have more than twice the specific capacity of graphite. In addition, if graphene and carbon black are mixed as a conductive additive and added to a lithium battery, the internal resistance of the battery can be effectively reduced, the battery charge and discharge performance and cycle life can be improved, and the bending of the battery has no effect on the charge and discharge performance. After the ene material, the battery has a high charge and discharge rate is the reason why graphene batteries have fast charging.

In the application of lithium batteries, the main functions of graphene include two: one is a conductive agent, and the other is an electrode-embedded lithium material. Both applications are competing with traditional conductive carbon / graphite. At present, there are mainly three forms of graphene added in lithium batteries: conductive additives, electrode composite materials, and direct use as negative electrode materials. At present, the research and development technology of graphene conductive agents has been relatively mature.

Graphene in lithium batteries

2.1.1 Graphene as a conductive additive for lithium ion batteries

Lithium battery cathode material conductive additive, which significantly improves charge and discharge and conductivity. The cathode material conductive additive is one of the most advanced industries in graphene lithium battery applications.

Graphene is a new choice for high-performance lithium battery positive electrode conductive additives. The excellent electron transport ability brought by its special structure with two-dimensional high specific surface area can significantly increase the electrode material capacity.

And reduce the internal resistance of the battery, improve the rate and cycle life, improve the high and low temperature and safety of the battery

can.

Global graphene conductive agent usage forecast

As for the graphene conductive agent, its excellent carrier mobility (15000cm2 / V-1 • s -1) and ultra-low resistivity (10-6Ω · cm) can significantly reduce battery internal resistance, Improve the rate performance and cycle life, and improve the high and low temperature and safety performance of the battery.

2.1.2 Graphene as a negative electrode material for lithium ion batteries

Graphene anode materials can improve the theoretical specific capacity and rate performance of negative lithium batteries. The pore structure of graphene makes the diffusion path of lithium ions in the negative electrode material shorter, which effectively improves the conductivity; graphene’s excellent mechanical properties and chemical properties make its composite electrode materials have structural stability, which can effectively improve the cycle stability of electrode materials .

Graphene-coated silicon is used in the negative electrode to increase the energy storage density and promote battery weight reduction. At present, the energy storage density of laboratory graphene-coated silicon composite materials can reach 800mAh / g.

2.1.3 Graphene is used in lithium ion battery functional coating aluminum foil

Graphene functional coating aluminum foil can effectively reduce battery internal resistance. Graphene coated on aluminum foil current collector

In addition, the formation of graphene functional coating aluminum foil can reduce the internal resistance of the battery by half without loss of capacity, and at the same time increase the battery’s cycle life by more than 20%.

2.1.4 Graphene used in lithium ion battery conductive paste

Graphene conductive additives significantly improve charge and discharge and electrical conductivity. Conductive additives are at the forefront of industrialization in the application of graphene lithium batteries. Graphene conductive paste technology is mature, the cost advantage is prominent, and it has been supplied in batches. At present, many companies have applied graphene in lithium batteries, and graphene has been mass-produced in terms of conductive additives.

2.1.5 Graphene-based lithium-sulfur batteries

Lithium-sulfur batteries with elemental sulfur as the positive electrode and metallic lithium as the negative electrode have a theoretical energy density of up to 2600 Wh · kg -1, and highly conductive graphene as a current collector. Compared with traditional metal current collectors, its light weight helps In order to improve the overall energy density of the battery, and due to its abundant elemental sulfur reserves and low price, lithium-sulfur batteries are regarded as one of the most promising next-generation high-energy secondary batteries, and have received widespread attention from researchers.

2.2 Graphene Fuel Cell Fuel cell is a kind of power generation device that directly converts chemical energy existing in fuel and oxidant into electrical energy. A fuel cell is a power generation device that directly converts chemical energy possessed by fuel into electrical energy.

Graphene is beneficial for solving technical problems and cost problems in fuel cells. Utilizing the transport characteristics of graphene membrane materials is expected to solve the fuel penetration problem of the core component of the fuel cell “proton conductive membrane”. At the same time, the use of nitrogen-doped graphene catalysts can obviously reduce the cost of fuel cells.

Graphene fuel cell

2.3 Graphene Paper Battery

Graphene oxide is made into graphene paper. Graphene paper can act as a proton conductor. The battery made of graphene paper has a good initial capacity. The incorporation of graphene can increase the specific capacity of batteries and the utilization rate of active materials by more than 10%.

Graphene is separately added to the negative electrode of the battery, which improves the high rate discharge performance and greatly extends the cycle life. The negative electrode plates with graphene have a high porosity of more than 70%.

Graphene paper has special properties such as excellent electrical conductivity and great specific surface area, which can increase specific capacity and active material utilization rate when used in batteries; graphene can maintain high porosity of lead paste, which is beneficial to increase the rate of battery Discharge ability and charge acceptance ability to extend cycle life.

2.4 Graphene supercapacitor

Super capacitor is an electrochemical energy storage device between traditional capacitors and secondary batteries. It has the advantages of high power density, fast charge and discharge, high cycle life, no pollution, and maintenance-free.

Various fields requiring energy conversion have great application value. But supercapacitors are currently subject to

Constrained by electrode materials, the energy density is generally lower than 20wh / kg.

Graphene itself has a very large specific surface area (2600 m2 / g). It can significantly increase the energy storage density when applied to supercapacitor electrodes. Its energy storage density is close to that of lead-acid batteries. It is an ideal electrode material for supercapacitors. A car made of graphene supercapacitors can run for 1,000 kilometers on a single charge in only 8 minutes. Graphene supercapacitors have an energy density of more than 600wh / kg, which is 5 times that of current power lithium batteries. The battery weight is only half that of lithium-ion batteries, and the service life is 2 times that of current lithium batteries and 4 times that of traditional hydrogen batteries. The lithium battery is reduced by 77%.

2.5 Graphene Solar Cell

Graphene has a high transmittance (97.3% for a single layer) and low sheet resistance. Using graphene can improve the photoelectric conversion efficiency and can be used as an acceptor material in solar cells. Graphene can be combined with organic polymer materials to form a large acceptor interface, which is conducive to the increase of exciton diffusion rate and carrier mobility in the battery, and eliminates secondary aggregation caused by the destruction of the charge transport path.

In addition, graphene materials are also applied to the photoanode of various solar cells. Depositing a graphene film on the silicon surface is beneficial to the surface passivation, doping, and formation of heterojunctions of the silicon battery, and effectively improves the photoelectric conversion efficiency of the battery.

With the country’s emphasis on the development and utilization of new energy, the production and sales of solar cells have the ability to continue to grow. The emergence of graphene has provided a solution to some technical problems that need to be solved in the photovoltaic industry. Graphene has great promise in the photovoltaic industry in the future.

2.6 Graphene stores hydrogen energy

As we all know, the amount of hydrogen absorbed by a material is directly proportional to its specific surface area. Graphene has a light weight,

The advantages of high chemical stability and high specific surface area make it the best candidate for hydrogen storage materials. The Greek University has designed a new 3D carbon material with adjustable pore size. When this new carbon material is doped with lithium atoms, the graphene column’s hydrogen storage capacity can reach 611%.

2.7 Graphene Functional Coating

Graphene’s high specific surface area, high thermal conductivity, stable chemical properties, and excellent mechanical properties make it an important “seasoning” for next-generation coatings, rubber, plastics and other products, which can comprehensively improve the characteristics of traditional products , And has little impact on the original production process and cost, making graphene the focus of new generation coatings.

Graphene used in coatings can prepare pure graphene coatings and graphene composite coatings, which can significantly improve the performance of polymers. Therefore, graphene composite coatings have become an important application research area of graphene.

2.8 Graphene Thermal Coating

The current thinning and thinning of electronic products has become a trend. With the enhancement of product functions and performance, high-power processing chips bring more heat, faster processing speed and lower power consumption. Cooling requirements. The carbon materials represented by graphene heat-dissipating films have become the most promising heat-conducting materials due to their high thermal conductivity, low density, low thermal expansion coefficient, and good high-temperature mechanical properties.

Graphene heat-dissipating coatings have huge application prospects and can be widely used in the heat dissipation of air-conditioning, LED lamps, high-power chips and other fields.

2.9 Graphene conductive coating

Conductive coatings are special functional coatings that have developed rapidly with modern science and technology. At present, they have been widely used in static dissipation, electromagnetic shielding, and electronic packaging.

Because of its high electron mobility and excellent electrical properties, graphene can better achieve the goals that conductive coatings need to achieve; and because of its excellent mechanical and thermal properties, graphene makes this new conductive coating more durable. It is more suitable for complex application environments and is an excellent conductive coating additive.

2.10 Graphene Conductive Adhesive

Using natural flake graphite as a raw material and using an aqueous emulsifier, a graphene conductive adhesive can be obtained under mechanical vibration. Graphene also has a wide range of applications in conductive adhesives. At present, the main fillers of commercial conductive adhesive products are carbon black, silver powder, nickel powder, etc., each of which has advantages and disadvantages. Although carbon black is cheap, it has poor electrical conductivity and requires a large amount of filling. Silver nickel powder has good electrical conductivity, but the price is high and the cost of the product is too high. Using graphene as a filler can not only reduce the amount of filler, but also resolve the contradiction between conductivity and cost. Therefore, graphene conductive adhesive can be used for LED packaging and electronic device packaging, reducing packaging costs.

2.11 Graphene Antistatic Coating

Antistatic coatings are widely used in many fields such as electronics, electrical appliances, aviation and chemical industry. With the development of modern technology, the requirements for antistatic performance are becoming higher and higher. Graphene’s high electrical conductivity and strong mechanical properties are conducive to the preparation of high performance and high strength antistatic coatings. Hexadecylamine was grafted onto the surface of graphene to increase the compatibility with epoxy resin.

The two are evenly mixed, and the amount of graphene in the mixed system can be changed to obtain antistatic coatings with different surface resistivities. When the amount of modified graphene is 0.5%, the surface resistance of the antistatic coating film can be reduced to 109Ω / sq, meet the standard requirements of antistatic coatings

2.12 Graphene Anticorrosive Coatings

Graphene is the thinnest anti-corrosion coating known. Graphene has been successfully applied as a metal protective film, and it has significantly delayed the corrosion rate of metals, and has a bright future. After adding graphene to the coating, graphene can form a stable conductive grid, which effectively improves the utilization of zinc powder. The anticorrosive effect of water-based graphene coatings is significantly better than that of other carbon-based materials filled water-based coatings. The coating has more outstanding salt spray resistance. Adding a small amount of graphene to the traditional phosphoric acid coating can make the coating’s salt spray resistance time more than double, and its cost performance is better than traditional coatings.

2.13 Graphene Transparent Coating

Graphene has good optical properties due to its single layer light transmission of 97.7%, and can be used in the fields of automobile and ship glass, displays, televisions, etc. on the basis of achieving anticorrosion and other goals.

2.14 Graphene Wear-resistant Coatings

The graphene waterborne polyurethane coating was prepared by the sol-gel method. Adding 2.0% of graphene can increase the tensile strength of the coating film by 71% and the Young’s modulus by 86%. The friction life is increased by 880% compared to pure polyurethane.

2.15 Graphene architectural coatings

Graphene has a high thermal conductivity, and its use in building insulation coatings can effectively reduce the internal temperature of buildings and enhance energy saving effects. Xue Gang et al. Used a reflow method to wrap graphene on the surface of the infrared emitting powder to prepare a composite heat-dissipating coating containing graphene, tourmaline and transition metal oxides. Graphene can reduce the thermal resistance of infrared particles. Compared with ordinary heat-dissipating coatings, the infrared emission rate of graphene-containing composite coatings reaches 96%, saving energy 6.37, Showing a good energy-saving effect. Graphene has excellent mechanical properties, which can significantly improve the tensile strength and toughness of polymers. Graphene is added to polymer cement waterproof coatings composed of acrylic polymers and cement. Graphene is rich in oxygen. The groups can regulate the growth of cement hydration products, and significantly improve the physical properties of the coating film (such as tensile strength, elongation at break, impermeability, etc.).

2.16 Graphene conductive ink

Graphene conductive ink is a kind of ink products with special functions such as conductivity, which is composed of functionalized graphene, binder, agent and solvent. It has the advantages of excellent electrical conductivity, light print quality, good printability, mild curing conditions, and low cost. It can print on a variety of substrates such as plastic films, paper and metal foils.

Graphene ink is suitable for screen printing, gravure printing, flexo printing, offset printing and inkjet printing. It can be applied to printed circuit boards (PCB), radio frequency identification (RFID), display equipment (such as OLED), electrode sensors, etc. Potential applications in organic solar cells, printed cells and supercapacitors. Therefore, graphene ink is expected to be widely used in the next generation of thin and flexible electronic products such as radio frequency tags, smart packaging, membrane switches, conductive circuits, and sensors, and the market prospect is huge.

Graphene conductive ink

2.17 Graphene grid anticorrosive and anti-icing paint

A new heavy-duty anticorrosive coating developed using new material graphene will be applied in the field of power grids. In the future, the anticorrosive and anti-icing capabilities of power grids are expected to be greatly improved.

There are a large number of chemical plants in the coastal areas, high levels of sulfur-containing exhaust gas in the air, and severe salt mist corrosion, which causes the corrosion rate of coastal transmission towers to be 3 to 5 times faster than inland areas, increasing maintenance costs and increasing grid operation risks . At present, the main heavy-duty anticorrosive coating on the market is a zinc-rich primer, which not only has a short protective life, but also uses a large amount of zinc, which wastes resources and is contrary to the concept of environmental protection. The zinc content in graphene heavy-duty anticorrosive coatings is only 20% or even zero, and the performance is at least doubled. Without increasing the thickness of the heavy anti-corrosive coatings, the anticorrosive life can be greatly extended. Once this coating is applied, it is of great significance to improve the safety of the national power system, guarantee the normal development of the national economy and people’s lives.

2.18 Graphene Antistatic Plastic

Polymer materials are insulators under normal circumstances, and usually have a surface resistance of 1012Ω · cm or more. Antistatic packaging materials require a surface resistance of 107-1011Ω · cm.

Graphene antistatic masterbatch added to plastic

It can avoid static electricity due to the insulating properties of the polymer material itself, so that it can adapt to the packaging requirements of IT products and the production of special antistatic products, and it has a good effect on the surface of products.

2.19 Graphene Conductive Plastic

In polymer materials, graphene is required to have good dispersing ability, in order to reflect the effect that a small amount of addition can greatly improve the conductivity of the material. Graphene microflake products can be smoothly added in various polymer materials such as polyethylene, polypropylene, and nylon, and are well dispersed.

In the polyethylene system, when the graphene microchip filling amount is 0.5% (mass fraction), the resistivity of polyethylene can be reduced to 106Ω · cm, and when the filling amount reaches 3% (mass fraction), the resistivity is reduced to 104Ω · cm. In the polyvinylidene fluoride system, through good dispersion and compounding technology, when the graphene filling amount is 3%, the resistivity can be reduced to less than 10Ω · cm. It can be seen that the application effect of graphene microchips is obvious.

By using graphene composite materials, the body material can achieve more conductive properties and avoid the use of copper mesh. By developing more conductive resins, adjustments can be made to some of the materials that make up the internal structure of the aircraft, such as computer housings and cabin structures, those that do not require as much testing as the main structures.

2.10 Graphene Reinforced Plastics

Graphene has a lot of application space in the automotive industry, and using it to strengthen automotive composite materials will have great potential. The addition of graphene nanomaterials can increase the impact resistance and compression performance of carbon fiber reinforced epoxy resin parts. This allows designers to develop lighter, more efficient carbon

Fiber-reinforced epoxy structure, where impact resistance is a major factor in design considerations. Applications for this new prepreg include aerospace, automotive, and sporting goods such as bicycle frames, fishing rods, and rowing boats. Graphene reinforced carbon fiber epoxy prepregs have significantly improved their structural thermal and mechanical properties. Using graphene composites can further develop a new generation of carbon fiber epoxy prepregs.

2.21 Graphene Tire

The graphene static conductive tire adopts the composite modification technology of graphene and gum to overcome the shortcomings of the existing towed car antistatic technology and equipment, such as sparks, short wear, short fall, and inability to reliably derive the car body static electricity. The tread of the tire with electrostatic conduction function is grounded, and the static electricity of the vehicle body can be discharged continuously and reliably in all periods.

2.22 Graphene Rubber Composite

Most rubbers need reinforcing agents such as carbon black to be filled in order to improve various properties of the rubber. Graphene is currently the thinnest, hardest, and most tough material known in the world. These properties make it an ideal reinforcing agent. And graphene has a very high specific surface area. Adding a very small amount of graphene can significantly improve the performance of rubber composites.

With the diversification of rubber products, many applications such as switches, sensors, sealing devices, etc. require rubber products to have other properties such as antistatic, electrical conductivity, or gas barrier properties. The excellent properties of graphene provide rubber products to meet various needs. Provides opportunities. Graphene constitutes a thermally conductive network in a rubber composite material while also forming a conductive network, which can greatly reduce the composite material’s conductivity threshold and increase its conductivity. Among them, graphene rubber tires are gradually industrializing. In addition, as a two-dimensional sheet material, graphene has excellent barrier properties to gas molecules, and has potential applications in improving gas barrier properties of rubber composite materials.

2.23 Graphene foam material for sports products Graphene material is used in sports products. Its light weight, high strength, wear resistance and good elasticity are beneficial to improving the comfort and durability of the company’s shoe products. Innovative materials. The use of graphene foaming materials can help enhance the competitiveness of sports goods companies, gain consumer recognition and form a brand effect.

2.24 Graphene Impervious Waterproof Plastics The use of graphene to develop impervious waterproof plastics has the same appearance and feel as ordinary plastics, but the waterproof performance is one million times better. Products wrapped with mixed graphene plastics have the potential to be stored for one year, which is a lot better than conventional plastics in less than 30 minutes.

2.25 Graphene Metal Composite

The application of graphene in metal-based protective materials is very promising. Metal-based graphene composites can improve the defects in strength, hardness, light weight, and processability of the original protective materials (steel plates, aluminum alloys, ceramic materials), and meet the demand for lightening armaments.

The performance of graphene composites on metals is very obvious. The strength of graphene-metal composites can be increased by 60% to 234% on the basis of pure metals, and it has also been greatly improved in terms of toughness, hardness, and thermal conductivity. Taking metallic aluminum as an example, its strength was originally poor, but the strength was greatly improved after the addition of graphene nanosheets. As an armor protective material, it would have both the protective ability of ceramics, the density of aluminum alloys, and the anti-strike ability of steel. “Weak” characteristics are very suitable for the needs of military equipment with high strength, high impact resistance, and light weight.

Graphene is the material with the lowest resistivity in the world. The resistivity is lower than that of copper, which is currently the preferred material for domestic wires and cables. Graphene may become a substitute for cable conductors. After the graphene composite semi-conductive shielding material is applied to medium and high voltage cables, the volume resistivity of the semi-conductive shielding layer inside and outside the cable can be greatly reduced, its thermal stability can be improved, the uniformity effect of the shielding layer on the electric field can be effectively reduced, and the cable operation can be effectively reduced The partial discharge phenomenon that may occur in the circuit ensures the safety and reliability of power line operation and improves the cable operating life.

2.27 Graphene Lubricants

By using graphene to improve lubricating oil, power can be enhanced, fuel consumption and automobile exhaust emissions can be reduced. Graphene enters the engine with lubricating oil, and forms a series of nano-spheres through a series of mechanical friction. It can produce a ball effect during friction, and can also fill and repair the surface of the friction pair of the engine. At the same time, because of the toughness of graphene, as a friction filler, it is not easy to be damaged and worn, thereby achieving the purpose of greatly reducing the wear rate of the engine and extending the service life of the engine.

2.28 Graphene Reinforcing Filler

Graphene’s excellent mechanical and electrical properties make it an ideal reinforcing filler for the preparation of high-performance polymer composites. Graphene-reinforced epoxy resin composites are 31% higher than single-walled carbon nano-reinforcements, and fracture toughness is 53% higher than multi-walled carbon nanotubes. Graphene has broad applications in the preparation of new polymer composites prospect.

Graphene can also be used as a sensor for aerospace materials to detect the atmosphere or the spacecraft itself. Graphene can be used as a lightweight and high-strength structural material for aircraft. Because of its high electrical conductivity, high toughness, high strength, and large specific surface area, graphene is widely used in aerospace and military industries.

2.30 Graphene heating assembly

Graphene heating components are expected to become an application growth point within 1-2 years. Graphene can be used for heating components, and automotive glass will be an important application area. Using conductive properties, graphene can be made into heating components by coating. Used for clothing warmth, industrial temperature control, etc. At the same time, some companies use this function for heating the front and rear glass of automobiles, which may become an important option for heating glass in the future.

2.31 Graphene fiber textiles Researchers have successfully developed the first fabric made of pure graphene fibers on the basis of continuous wet spinning technology. This graphene fiber non-woven fabric has very good flexibility, with conductive and thermal conductivity of 28000S / m and 301W / mK, respectively, and a density of only 0.22g / cm3. Reported carbon-based two-dimensional fabrics, film materials, and commercial carbon fiber paper. Compared with commercial electric heating elements, graphene fiber nonwovens have significant advantages such as fast thermal response and high operating temperature. At the same time, the non-woven fabric’s adsorption capacity and adsorption speed for organics are significantly better than commercial linoleum. Based on the above excellent properties, graphene fiber non-woven fabrics can be used as electrode materials in the energy field, fast and efficient electric heating fabrics, and oil-absorbing paper that absorbs organic matter.

2.32 graphene aircraft

The properties of graphene as a new material in terms of heat, mechanics, electricity, etc.

Researchers in the aerospace and automotive fields are thrilled. It can be used as a nano additive, while improving the mechanical strength of thermosetting plastics and thermoplastics, it can also reduce the weight of the material. If it is further optimized, it can also add heat and electricity related features to ordinary plastics, so that a single function material can be turned into a multifunctional material.

In the field of aerospace, graphene has great potential. The use of graphene allows the UAV wing to have both high strength and low weight. In terms of impact resistance, the graphene wing is 60% stronger than the carbon fiber wing.

2.33 graphene highly conductive composite film

Graphene highly conductive composite film can be used in a variety of fields such as aircraft deicing, electromagnetic shielding, non-metal conductive electrodes, flexible heating materials, etc., especially in graphene heating wearable products, to solve the problems that plague the comfort of existing heating materials , Applicability, and unity. Therefore, the launch of this graphene highly conductive composite material has achieved good advantages in technical performance indicators, which will further promote the industrialization of graphene materials and have a huge market prospect.

2.34 graphene brake pads

Through the process of mixing, pressing, sintering, heat treatment, strengthening treatment, mechanical processing and other artificial graphene, the production of graphene automobile brake pads is finally completed.

Graphene brake pads are 13 times more resistant to high temperatures than conventional brake pads, have four times the impact strength of conventional brake pads, 6 times the wear resistance of conventional brake pads, and 15 times the acid and alkali resistance of conventional brake pads.

2.35 Graphene 3D Printing Materials

Adding graphene to the commonly used polymer materials for 3D printing has changed the properties of the polymer in many ways, it has improved the mechanical strength of the polymer and its electrical and thermal conductivity.

Compared with traditional display screen conductor materials, graphene has better performance, and the flexible characteristics of graphene can increase the service life of touch screens. With the advancement of flexible display technology, graphene films are used in the LCD display and wearable device markets China is expected to usher in a wide range of applications.

Graphene has high light transmission, strong toughness, and excellent electrical conductivity. It is the most ideal material for new transparent conductive films, and it has good flexibility and easy bending. It is the most ideal replacement material for new transparent conductive films.

2.37 graphene nano silver wire composite flexible transparent conductive film

The graphene nano-silver wire composite product has a small bending radius, and the resistance change rate is small during bending, which can be better extended, and at the same time has a higher light transmittance. It has obvious advantages when applied to curved display devices.

2.38 Graphene Touch Products

Graphene touch products will be widely used in various interactive display scenarios to replace mechanical button panels. The graphene touch screen has excellent performance, and has two characteristics of flexibility and wide temperature adaptability. At present, domestic and foreign graphene touch screens have been successfully developed and put into production. South Korea’s Samsung Corporation and Sungkyunkwan University are researching and manufacturing pure 63 cm wide graphene and using this graphene to make flexible touch screens. Both carbon and the sixth element have mass production of sensors and touch components; Chongqing Moxi Technology Co., Ltd. and Jialepai Technology Co., Ltd. have released graphene mobile phones.

Graphene is transparent, flexible, and highly conductive. It can be arbitrarily changed. It can better fit the human body in wearable devices and achieve consumption breakthroughs. At present, the graphene flexible screen has achieved breakthroughs in technology. For example, the successful development of electronic skin has achieved the function of arbitrarily bending and deforming, imitating human tactile perception.

In recent years, with the gradual increase in the global production and sales of electronic equipment, especially the rapid development of industries such as smartphones, computers, car displays, and wearable devices, graphene has excellent flexibility, high conductivity, and high light transmission Features, will have the potential for rapid promotion in emerging areas such as wearable devices.

2.40 graphene chip

Compared to silicon chips, graphene chips have greatly improved performance. Scientists believe that the use of graphene to make transistors may eventually replace existing silicon materials and become the basis for future ultra-high-speed computers. The smaller the size of a graphene transistor, the better its performance.

Integrated circuits made of graphene have stable performance in a small size, high frequency and low heat generation, and faster data transmission speed, which will make faster computing capabilities a reality. This can not only promote the progress of the chip industry, but also the development of artificial intelligence and cognitive computing. In the future, the technology of graphene chips may bring a revolutionary change to the chip and related industries

2.41 Graphene Spin Electronic Circuit Switch

Graphene has spin filtering, making it possible to obtain highly spin-polarized carriers. This principle is the same as the filter, which only allows electrons in one spin direction to pass, blocking other spins.

Electrons in the direction of rotation, so that the “up” and “down” of the electrons can be distinguished, thereby forming “0” and “1” in digital logic, and realizing the switching function of the circuit.

2.42 Graphene Monoatomic Magnet Storage Device Physicists at the Lausanne Institute of Technology in Switzerland used a single atom magnet to pave a superlattice structure on graphene, and successfully developed a prototype of a single atom-based storage device. The device has a data storage density of 115 TB per square inch, which heralds the next generation of storage media.

2.43 Graphene OLED electrode

The Fraunhofer Institute in Germany and Dresden’s electron beam laser technology have successfully prepared OLED graphene electrodes for the first time. The center area of the electrode is 2cm × 1cm. It is expected to be used in other fields in the future. The first batch of OLED graphene-based electrode products will be produced and put into use within two or three years.

2.44 Graphene Camera Photosensitive Element

Graphene is a highly sensitive material that allows most light to pass through. Graphene photodetectors can absorb as much light as possible to build a clearer image without sacrificing the clarity of the image. According to Nokia’s official sources, there are two Nokia high-end Android phones under development, namely Nokia C1 and Nokia P1. Their biggest highlights are camera photosensitive elements or graphene materials. The screens are 5.2 inches and 5.5 inches respectively. They are equipped with Android 7.0 system and will be equipped with 2K resolution AMOLED panels. They will be designed with metal body and Nokia style.

2.45 Surface Plasmon Resonance Graphene Optoelectronic Device

Directly emitting diodes can be made by placing graphene on the surface of P-type gallium nitride, which can emit light under both forward and reverse current. A layer of silver nanoparticles is spin-coated on the surface of gallium nitride, and then a layer of graphene is placed. Using the plasma field enhancement effect of silver nanoparticles, the device’s luminous brightness can be more than doubled. When graphene is connected to a positive pressure, the device emits Yellow-green light near 565nm; when graphene is connected to a negative voltage, the device emits pure blue light near 395nm.

After a simple spin-coating of a layer of gold nanoparticles on the surface of a graphene heterogeneous device, the plasmon resonance is used to focus the solar light field on the graphene surface, which improves the efficiency of the solar cell by 30%, and can further increase the efficiency to 16.2% after further optimization And the efficiency of the device did not decrease after 100 hours of light.

2.46 Graphene photodetectors In the field of optoelectronics, graphene, a structure with no energy gap, is attracting the attention of many researchers. This feature is particularly prominent in the field of photodetectors. Graphene makes more efficient near-terahertz photoelectric The detector becomes possible.

The new graphene photodetector can detect light energy that is 100,000 times smaller than the detection level of existing photodetectors.

2.47 Graphene Laser

The new graphene-based superlattice material can excite surface plasmons in a wide range of wavelengths in the visible and near-infrared bands, and light-excited this superlattice material can obtain a wavelength-tunable Raman nanolaser. This Raman nano laser has the characteristics of no threshold, room temperature operation, adjustable laser wavelength, and wide laser wavelength coverage—from visible light to near-infrared light. It is hopeful that it will be applied in nano-light technology such as biomedical imaging. New breakthroughs.

2.48 New Graphene Deep UV Photodetectors Deep UV photodetectors have irreplaceable advantages of infrared photodetectors in the military, especially in the fields of ultraviolet communication, missile early warning and tracking, and electronic countermeasures. Introducing graphene and high-quality β-Ga2O3 single-crystal electronic materials with good light transmittance and high electron mobility into the structure of the deep ultraviolet photodetector, resulting in a simple structure, low cost, but high detection rate and good stability. The deep ultraviolet photodetector, spectrum analysis results show that the deep ultraviolet photodetector has very strong spectral selectivity, and the response is very obvious in the deep ultraviolet region. These excellent characteristics make the deep ultraviolet photodetector important in the photoelectric system. Potential applications.

2.49 graphene light modulator

Graphene has demonstrated significant optical properties, including visual transparency defined by fine structure constants and a gateable tunable endogenous plasma. Recently, graphene has been combined with other 2D materials such as hexagonal boron nitride (hBN) to form structures for developing LEDs. Combining graphene, hexagonal boron nitride, and nanoscale gold gratings can create a new class of light modulators. The use of light instead of electrical signals allows a significant reduction in the size of these circuits, which paves the way for faster circuits.

2.50 graphene electrostatic speaker

An electrostatic speaker is a speaker that emits sound by vibrating the diaphragm back and forth under the action of electrostatic force. Its diaphragm is extremely light, so its resolution is very good, it can capture very subtle changes in the music signal, and fully express the charm of music. Used in automobiles, airplanes, companies, leisure venues, retail stores, theaters, conference rooms, outdoor and indoor concerts, clubs and exhibitions.

Graphene electrostatic speaker developed using graphene resin composite material, compared with metal composite resin film, graphene electrostatic diaphragm process is simpler, lower cost, longer life, not easy to oxidize,

It has good flexibility, good transparency, wider sound range, and can represent mid and low frequencies that are not found in metal resin composites.

2.51 new graphene diaphragm sounding unit

Some scientists have made a sounding unit of graphene diaphragm. The sound effect is very ideal, light and low energy consumption. Based on this scientific research technology, the battery-powered portable wireless diaphragm headset can extend the battery life by 50%. A portable wireless earphone with an acoustic diaphragm sounding unit.

Graphene is much lighter than ordinary diaphragms, and will rebound to its original position very quickly. There is almost no need to consider energy loss when designing. Traditional speakers can’t do this and need to use more power to drive. In addition, this advantage can also improve the frequency response curve to achieve better sound quality, which can effectively improve the battery playback time of portable headphones.

2.52 Graphene Ultrasonic Microphone

A new type of ultrasonic microphone made of graphene can receive sound signals other than human hearing. Graphene is used to replace the traditional microphone diaphragm. Researchers have used this graphene-enhanced microphone to make devices that can receive ultrasonic radio waves, such as dolphins and bats’ ultrasonic signals.

A single layer of atomically thick graphene is thin, light, and strong, so it is extremely sensitive to vibration. In addition to the hearing range of a microphone based on graphene, which can cover the human hearing range (from 20Hz to 20kHz), it can also detect sounds up to 500kHz. However, the hearing range of a bat is only 9kHz-200kHz. No matter from the fields of natural science, military, or civilian use, graphene microphones have great potential.

2.53 graphene electronic flow state control equipment

School of Materials Research, Pennsylvania State University, USA

This device not only provides experimental evidence of electronic momentum control, but more importantly, because it requires the least energy and emits less heat than complementary metal oxide semiconductor (CMOS) transistors, it may open up a new one for electronics Branch.

Enter a pair of grids above and below the two-layer graphene sheet, and then add an electric field perpendicular to the plane. By applying a positive voltage on one side and a negative voltage on the other side, an energy band gap that does not normally exist in double-layer graphene can be opened in the double-layer graphene, leaving a gap between the middle and both sides of the double-layer graphene. A physical gap of about 70 nanometers controls the flow of electrons.

2.54 Graphene Preparation of High Current Materials

Recent experiments have shown that graphene can withstand the passage of extremely strong currents. This allows the offset charge to quickly balance. Graphene proves its magic again.

An international research team led by the Institute of Applied Physics at the Technical University of Vienna conducted an experiment that proved that the electrons in graphene are extremely mobile and the reaction speed is extremely fast. Collision of xenon ions with the ultra-high charge on the graphene film can detach a large number of electrons at a very precise point on graphene. However, in a few femtoseconds, graphene can quickly recharge electrons. This will lead to the emergence of super strong current which is impossible to sustain under normal circumstances. This extraordinary electronic property makes graphene a powerful candidate for future applications in the electronics field.

2.55 graphene electromagnetic shielding material

With the rapid development of the modern electronics industry, mankind has entered the era of electronic information, and more and more electronic and electrical equipment has entered all corners of society. However, these electronic electrical equipment will generate certain electromagnetic waves during operation. It will produce certain electromagnetic interference to the surrounding electrical and electronic equipment, and will also cause certain electromagnetic radiation harm to the human body.

In order to effectively suppress electromagnetic interference and electromagnetic radiation hazards, research on electromagnetic shielding materials appears

especially important. The polymer team of Ningbo Institute of Materials Technology has been committed to the development of efficient electromagnetic shielding materials, and has made a series of advances in the preparation and performance research of graphene-based electromagnetic shielding materials. Recently, the team has made important progress in the structural design and performance research of graphene-based electromagnetic shielding materials.

2.56 Graphene Near Field Communication Antenna

NFC technology is a set of communication protocols that guarantees the transmission of data between two devices. The biggest feature of NFC is that it can wirelessly transmit a small amount of data at short distances (typically within 5 cm). With such a short transmission distance, data will be more secure and less vulnerable to theft. Currently, the application areas of this technology include inventory, assets, personnel, animal tracking and management, contactless payment systems, security cards and social networks.

Research by the Italian partner CNR-ISOF of the graphene flagship project shows that graphene can be used to make fully flexible antennas. Graphene Flagship designed this antenna by combining material characteristics, computer modeling, and device technology. It can use near-field communication devices such as mobile phones to exchange information and match the functionality of traditional metal antennas. Graphene-based NFC antennas are chemically inert, resistant to thousands of bends, and can be placed on flexible substrates and wires of different standards.

2.57 Graphene Resonator

Graphene has very strong electrical conductivity and exhibits high metal conductivity. Even without the restriction of carriers, Johnson noise is very low, and the additional (1 / f) noise caused by heat exchange is maintained at a very low level. These characteristics undoubtedly make graphene an ideal material for resonator resonator beams, which can be used for the detection of micro mass, pressure, molecules, and DNA. It is very suitable for cell adsorption and environmental change monitoring. It has high sensitivity, small volume, and high resonance frequency. The research and application of

can. By chemically and biologically modifying graphene so that it has specific sensitive characteristics to a certain gas or biomolecule, a rapid and directional detection of the gas or biomolecule can be achieved, and a toxic chemical gas can be quickly and specifically detected.

2.58 Graphene Pressure Touch Sensor

With the release of the iPhone 6s in 2016, 3D-touch has become a hot spot in the mobile phone industry. 3D Touch technology refers to the screen can sense different touch pressures to give more rich functions.

Graphene pressure touch sensor with its ultra-small structure, with single-point, two-point, and four-point distributed installation modes, realizes single-point, partitioned two-point, and tactile feedback functions. Compression strength from milligrams to 5 kg. The sensor can realize multiple functions such as multi-level pressure induction, tap, tap, nail tap, shell vibration, etc .; it can be used for multi-level press menu selection, multiple game operation physical examination, real pressure handwriting, pressure password, replacement Various scene application environments, such as bezel keys, provide sufficient imagination for software and hardware design; it has passed various reliability tests such as fatigue presses of more than 500,000 times, high temperature and high humidity, high and low temperature cycle impact; It has the advantages of convenient use, small size, economical applicability, and easy installation and integration. It will be promoted to multiple applications such as medicine, medical treatment and environmental protection in the future.

2.59 Graphene Stress Sensor

Graphene is suitable for making high-sensitivity stress sensors. Graphene not only has nanometer size, but also has quasi-continuous characteristics. This quasi-continuous nano-graphene film can be transferred to a flexible substrate to make flexible and transparent high-sensitivity stress sensors, and then applied to artificial electronic skin and other fields. And because the graphene sensor has strong stability and small size, the graphene electronic skin is made.

The thickness is small and can be stuck on the finger to detect joint activity; Nokia and the Chinese Academy of Sciences have announced progress in graphene electronic skin; the stress measurement range exceeds 30%, and the sensitivity factor is increased to more than 500.

2.60 graphene chemical sensor

Graphene can be stretched on a silicon support and inserted between two independent liquid reservoirs. When a voltage is applied to the fluid cell, ions are pushed through the thin graphite layer. When a thin layer of graphite is drilled into small nanopores, the voltage causes particles to flow through the pores and displays an electron flow signal. Although ions and water cannot flow through graphene, graphene films can attract different ions and other compounds to their two close-to-atomic surfaces, thereby changing the electrical conduction of graphene for chemical sensing.

2.61 Graphene Biosensor

Graphene is an excellent material for biosensors. Graphene has excellent electronic, optical, thermal, chemical, and mechanical properties, making it a triple function of building probe molecules and signal transmission and amplification, making it an ideal material for ultra-sensitive biosensors. Fast electron transfer and multiplexable chemistry make it possible to achieve accurate and highly selective biomolecule detection. Graphene and its composites are increasingly used in the preparation of biosensors. The research focus of graphene in the field of biosensors focuses on the following two aspects: first, graphene electrochemical biosensors, involving enzyme sensors (for detecting hydrogen peroxide, glucose, ascorbic acid, dopamine, uric acid, etc.), and immunosensors ( It is used to detect viruses, bacteria, cancer markers, etc.), DNA sensors, protein sensors, etc. The second is graphene optical biosensors, including fluorescence sensors and resonance-based energy transfer sensors.

Graphene-based biosensors include current sensors, resistive sensors, field effect transistor sensors, FRET sensors, and so on. The target molecules are modified by graphene’s rich surface functional groups, which can not only transfer electrons quickly, but also realize the selective detection of biological molecules.

2.62 graphene blood analysis sensor

A blood analysis sensor made of graphene can be used in blood tests to minimize the amount of blood the patient needs to give. By chemically modifying graphene, a highly sensitive graphene sensor can be developed, which can detect various components with a small amount of blood.

2.63 Graphene Gas Sensor

Another important reason for the use of graphene as a gas sensor is its unique electronic structure. The adsorption of certain gas molecules can induce the electronic structure of graphene to change, which can cause its conductive properties to change rapidly. This principle is used. Detection of single molecules of gas (N02, NH3, H2O, CO, etc.) is possible.

2.64 Graphene Electrochemical Analysis

A chemically reduced graphene oxide-modified glassy carbon electrode was used as a new electrode system, and a new experimental platform for electrochemical sensing was proposed. Direct electrochemical behaviors of three metal proteins such as cytochrome C, myoglobin, and horseradish peroxidase (HRP) on graphene oxide-modified electrodes. It was found that graphene can promote its electron transfer kinetics and its biological activity Hardly affected. Defects and oxygen-containing groups on the surface of graphene oxide have chemical and electrochemical reactivity, which can be used to chemically bond and fix biological macromolecules for the development of biosensors. There are also many examples of non-covalent immobilization methods based on graphene for biosensor research; immunosensing is an important class of bioaffinity sensing

In addition, it occupies an important position in biological analysis; graphene oxide has developed a sandwich-type immunosensor. The excellent performance of the sensor is due to its fast electron transfer speed and large specific surface area.

2.65 Graphene Gene Sequencing

Researchers drilled nanopores in graphene and verified that long DNA molecules can pass through the graphene nanopores as if they passed through the eye of a needle through ion exchange in the pores. The nanopore on graphene is the first nanopore small enough to distinguish between two neighboring nucleobase pairs.

By detecting the flow of ions through graphene nanopores, the thickness of graphene in the fluid is less than 1nm, which is several times thinner than the thin film that separates single animal or human cells. Graphene is the most widely used in fluid tank separation in the world today. Thin film.

2.66 Graphene Quantum Dot Imaging

The outstanding performance of graphene quantum dots will open up new applications in biomedicine. Physics, nanostructures that limit the three-dimensional scale to 1-100nm and have significant quantum confinement and size effects are called quantum dots, such as silicon quantum dots, carbon quantum dots, and emerging graphite dilute quantum dots. Compared with organic fluorescent dyes commonly used for cell labeling and staining, quantum dots have excellent optical properties such as high fluorescent intensity, good stability, and stable properties. In addition, graphite dilute quantum dots have good biocompatibility and good optical properties. For example, graphene quantum dots are more stable than fluorescence in biological imaging, and do not exhibit photobleaching and non-light decay. Therefore, it can be widely used in the research of biomedical fields such as cell imaging, nano-drug transport system, bio-detection, bio-imaging, tumor treatment, bio-sensor and so on.

2.67 Graphene Cardiovascular and Cerebrovascular Imaging Graphene can be used as a film of an extremely sensitive photographic system when visually drawing a weak electric field in a liquid. Researchers expect this new method to be applied to the human cardiac and cerebrovascular electrical signal network. Visual research and provide richer and finer imaging. This ability to visually draw extremely weak electric field strengths and motions can also be applied to developments called microchip labs. This device uses tiny amounts of liquid on microchip equipment for medical research, such as diagnosing diseases or boosting drug development, or automating a series of other biochemical analyses. This device also has great potential for detection and retention of special chemicals and research and development of optoelectronics.

Researchers say that graphene can be used for cardio-cerebral vascular imaging to more easily measure the propagation of electrical pulses from a single cell within a network of more than 100 living cells.

2.68 Graphene Contrast Agent

People who have taken X-rays and performed magnetic resonance imaging at the hospital should know that before performing these tests, patients need to take contrast agents (contrast agents) to help display the images. The dose of contrast agent is a delicate issue. On the one hand, the doctor needs enough contrast agent to achieve a certain display effect, and on the other hand, he must also consider the toxicity of the contrast agent to the human body.

Researchers at Rice University have developed graphene-based developers that do not contain any metals. The absence of metal elements is not the point. The point is that after testing, the researchers found that the new developer had no signs of toxicity at all. The introduction of fluorine element in graphene and graphite can obtain clearer magnetic resonance images.

2.69 Graphene Drug Carrier

Because graphene has a monoatomic layer structure, its specific surface area is very large, and because of its good biocompatibility, it is very suitable for use as a drug carrier. U.S. scientists first prepared polyethylene glycol function

Graphene makes graphene very water-soluble, and can maintain stable dispersion in physiological environments such as plasma, and then successfully uses the π-π interaction to load the antitumor drug camptothecin derivative (SN38) for the first time On graphene, the application research of graphene in biomedicine was opened. Chinese scientists and others have used hydrogen bonding to use soluble graphene as a drug carrier to achieve high-efficiency loading of antitumor drugs on graphene. Because graphene has a high specific surface area, the load of doxorubicin on graphene can reach 2.35 g, which is much higher than other drug carriers.

2.70 Graphene for chronic diseases such as diabetes

Researchers at the Korea Institute of Basic Science’s (IBS) Nanoparticle Research Center have created a graphene-based diabetes patch that uses human sweat to allow accurate monitoring of diabetes and feedback on treatment results. Researchers have improved the detection capability of this biomedical device by integrating electrochemically-functional soft functional materials on a hybrid of gold-doped graphene and serpentine gold mesh. Just as enzyme-based glucose sensors are affected by pH and temperature, the pH and temperature monitoring capabilities of this device can systematically correct sweat glucose measurements.

Graphene-based wearable devices not only monitor sweat glucose levels and pH, but also control the transdermal administration of drugs through temperature-responsive microneedles. Accurate sweat glucose measurements are used to estimate glucose levels in a patient’s blood. This device still retains its initial sensitivity after multiple uses, thus allowing multiple treatments. Connect this device to a portable / wireless power and data transmission unit for instant treatment of diabetes.

2.71 Graphene distinguishes ordinary cells from cancer cells

After cells and graphene interact, they can be distinguished by Raman imaging technology.

Cancer cells and ordinary cells, which makes graphene promising for cancer detection. When normal cells and cancer cells interact with graphene, the energy of the atomic vibration generated in the graphene lattice is not the same, so different conditions will be shown under Raman imaging, so you can distinguish whether there is cancer cell.

In addition, graphene cell detection technology can also be used in bacteria to quickly check whether the bacteria are Gram-positive or Gram-negative.

2.72 Graphene Medical Antibacterial Graphene oxide is a substance that can destroy cell membranes. Its method of destroying bacteria and fungi mainly depends on the cutting effect of graphene. It is sharp like a knife and can easily destroy cells, causing the contents of the cells to leak, leading to cell death. At the same time, it has several advantages, low cost, easy mass production, and no pollution to the environment. This method has many advantages over previous disinfection, and it is relatively cheap. It kills germs by physical cutting. Using a physical sterilization method such as graphene, you no longer have to worry about the “super bacteria” produced by antibiotics. “. Articles disinfected in this way will not remain in the human body during repeated use, which greatly reduces the harm to the human body. For patients with decreased immune function, it is of great significance.

2.73 Graphene for Bacterial Infection

The Changchun Institute of Applied Chemistry, Chinese Academy of Sciences uses graphene / mesoporous silica nanosheets (GS) coated with hyaluronic acid as nanocarriers and ferromagnetic nanoparticles (MNPs) as catalysts to build a targeted and capable A drug-loading system AA @ GS @ HA-MNPs that releases prodrug ascorbic acid (AA) “on demand” to treat bacterial infections. When the drug-loaded nanoparticles reach the infection site, the encapsulated hyaluronic acid is degraded by the hyaluronidase secreted by the target bacteria, and the loaded AA is gradually released.

MNPs that are released and then adhered to the surface of the bacterial membrane catalyze the production of highly toxic OH. Because graphene has excellent photothermal properties, this system can achieve chemo / photothermal synergistic antibacterial effect. The antibacterial system also has a broad spectrum of antibacterial properties, and it has a high-efficiency killing ability against both Gram-positive bacteria (such as Staphylococcus aureus) and Gram-negative bacteria (such as E. coli). In addition, because the coating components can be degraded by OH, the antibacterial system can also effectively disperse the stubborn biofilm and kill the bacteria it protects.

2.74 Graphene for Damaged Muscles According to the Iranian National Commission for the Revitalization of Nanotechnology, researchers used polymer nanofibers and graphene to synthesize scaffolds for repairing damaged muscle tissue. The scaffold made in this laboratory can be used to repair damaged muscle tissue in actual treatment.

Because graphene has better performance, fewer additives and fewer materials can be used. Graphene is used to improve mechanical and electrical properties, and it can also improve the biocompatibility of polyaniline.

The addition of graphene sheets increases the conductive properties of the scaffold and promotes cell differentiation. It was also observed in experiments that when graphene and graphene oxide nanosheets were used, cells behaved differently. The results have now been published in biomedical engineering materials.

2.75 Graphene Foam Promotes Organ Regeneration

American scientists have discovered that graphene foam can provide a three-dimensional platform for myotube growth. By studying the application of graphene foam in muscle tissue, it has been shown that graphene foam is very suitable as a scaffold material for growing functional muscle tissue.

2.76 Graphene Medical Wearable Device

Graphene has the unique properties of rapid thermal conductivity, and has obvious advantages in the field of heating and warming.

The 8 ~ 14 micron far-infrared light generated during the fever is the most suitable band for human health. It can produce the most effective “resonance” with the water molecules of cells in the body, promote the growth of organisms and blood circulation, and strengthen the metabolism between various tissues. And increase the regeneration ability, improve the body’s immunity, and thus play a medical and health care role, so in the past two years, smart inner warm clothing with graphene heating film has been sought after.

For example, the graphene far-infrared intelligent moxibustion physiotherapy service uses the characteristics of the far-infrared band of the graphene heating film and the human body’s far-infrared band to match the principle of moxibustion of traditional medicine to achieve warmth and cure diseases. The graphene physiotherapy patch contains a graphene heating film, which can be affixed to various parts of the lining of the physiotherapy clothing to generate heat. The thermal energy generated by the carbon atoms in the graphene heats up within 3 seconds, and can be heated to 20 ° C to 60 ° C. The box can freely adjust the temperature, and the USB cycle charging can be used for a long time. Combined with graphene physiotherapy moxibustion package, it will achieve better results, safe and intelligent.

2.77 Graphene TCM Pulse Bracelet

Changzhou 2D Carbon Technology Co., Ltd. The first batch of 1,000 TCM diagnostic pulse bracelets went offline on August 26. The core of TCM pulse diagnosis bracelet is a flexible pulse sensor made of graphene circuit. The diagnostic pulse bracelet is connected to the mobile phone through software, which can realize long-term real-time monitoring and remote diagnosis and treatment.

The core component of the pulse diagnosis bracelet is the graphene pressure touch sensor, which has ultra-high sensitivity, and also has the advantages of convenient use, small size, economical applicability, and easy installation and integration. At present, it has passed various reliability tests of more than 500,000 times of fatigue compression, high temperature and high humidity, high and low temperature cycle impact. The graphene pressure touch technology and big data calculation make the traditional closed TCM diagnosis pulse become standardized and big data. At present, two-dimensional carbon combined with downstream companies has formed a complete product system of pulse diagnosis data collection, filtering algorithms, back-end TCM databases, and artificial intelligence deep learning algorithms, which perfectly presents the waveform of the human pulse and is expected to become a revolution in TCM auxiliary diagnosis

Sex products. It is reported that this traditional Chinese medicine diagnostic pulse bracelet is now in clinical trials in some hospitals in Hong Kong, and will be fully marketed soon.

2.78 graphene hydrogel The new graphene conductive hydrogel combines mechanical properties, electrical conductivity, self-adhesion, self-repair performance and biocompatibility. Compared with commercial electrodes, graphene conductive hydrogels can be adhered multiple times, thereby collecting reliable and stable signals multiple times. In addition, graphene hydrogels can also be implanted in vivo as bioelectronic devices to study the behavior of living tissues.

2.79 Temperature-controllable graphene heating wallpaper Graphene’s application in civil heating equipment has just risen. One of the more noticeable is the graphene heating wallpaper. Turn the heater into a 0.5cm thick wallpaper, turn the traditional bulky body into simple, novel home furnishings, and start a new era of smart home. The graphene ink wallpaper and electrodes are used to prepare a graphene heating film. The uniform resistance layer formed mainly by the graphene film is heated under the voltage of 220V. The graphene film is mainly used to release far infrared rays to achieve space. Of heating.

Graphene heating wallpaper is mainly composed of three layers of materials, which are: insulation layer, heating film, wallpaper, and an external intelligent temperature control device, which can realize APP remote control. Its unique heating principle and revolutionary ultra-thin thickness give it the following advantages:

① Safe and flame retardant. The graphene heater is integrated into the interior of the wallpaper, and the surface temperature does not exceed 55 ° C, which completely eliminates the hidden dangers of high-temperature burns and prevents leakage. The insulation board is made of flame-resistant building materials, and the wallpaper itself is extremely flame-retardant. The production process of high-temperature flame-retardant heating wall cloth is used to meet national safety performance indicators, which is safe and reliable.

② High efficiency and energy saving. Graphene heating source with super thermal conductivity, fast heating, high efficiency, uniform heating

Dissipate evenly and dissipate heat immediately in 1 minute. Super heat-conducting material, the electrothermal conversion rate is above 99.5%, which is 45% higher than the traditional heating material’s electric energy conversion.

③ Fashion and diversity. It’s a heater, and it’s a stylish wallpaper. The heater is only 0.5cm thick and seamlessly glues the wallpaper. The wallpaper offers a variety of colors and textures, fashionable personality, to meet the decoration needs of different families.

④ Health physiotherapy. Radiation cooling method, ultra-quiet operation, prevent air drying. Due to the unique properties of graphene, it can radiate 8-15um far-infrared light waves, which is similar to the far-infrared light waves radiated by the human body. It is medically called “life light waves”, which can promote cell activity and metabolism. Health physiotherapy effect.

⑤ Heat and moisture resistant. The wallpaper can withstand high temperature above 90 ℃, and it has high strength without deformation. In the southern region during the rainy season, the air is very humid. Using hot wallpaper can quickly evaporate indoor moisture, dehumidify and prevent mildew on clothing, mold and moisture, and prevent eczema in children.

⑥ Smart and convenient. The remote mobile APP intelligently controls the temperature, through the intelligent temperature data collection, establishes the health file, the automatic temperature adjustment, saves the electricity and the peace of mind.

Compared with the high cost of underfloor heating, the soil shape of Youting, the hidden dangers of the little sun, and the emergence of graphene heating wallpaper is the embodiment of modern people’s pursuit of quality life and green life-health, fashion, convenience, energy saving and simple sense of space . This is all that graphene heating wallpaper can give. In the future, graphene heating wallpaper will generally appear in every modern home.

2.80 graphene environmental protection material

Graphene is currently the material with the highest adsorption capacity. The thin layer structure of graphene makes it have a large specific surface area, and it can produce a very strong complex reaction with organic pollutants. It has a good adsorption effect on heavy metal ions and toxic non-metal ions in water. It has great potential in wastewater treatment such as drinking water treatment, electroplating industry, printing and dyeing industry, leather processing, etc.

Graphene’s thin layer structure makes it have a large specific surface area and has a high adsorption capacity for solids, gases, and ions. Although graphene-type adsorbents are still in the laboratory stage and there are no mature products, they are still the most promising materials for unifying all adsorption ranges of carbonaceous adsorbents in the future, and have broad application prospects.

Application of graphene in environmental protection

Graphene oil-absorbing sponge

Existing oil-absorbing products generally can only suck liquids that are about 10 times their own mass. The actual measurement value of graphene oil-absorbing sponge oil absorption capacity is 400-500 times its own mass, which is 2-4 times the best known product with the best oil absorption performance, and the theoretical value can reach 900 times its own mass. Each gram of graphene sponge can absorb 68.8 grams of organic matter per second. In addition, the elasticity of the graphene sponge is not affected by temperature and has no temperature dependence. It can even work in extremely cold or hot areas. Because of its elasticity, the absorbed oil can be pressed out for recycling, and the graphene sponge can be reused. Graphene purification of sewage

Graphene film can shield all molecules except water. Graphene is expected to be used in the preparation of filter materials, and has great application prospects in seawater purification and sewage treatment. Graphene-coated gravel can be assembled into a filter material, which has a 5 times higher mercury removal capacity than other adsorbents. The graphene-magnetic iron nanoparticle composite is used to separate arsenic from water. Graphene is expected to replace existing

Carbon adsorption material has become one of the best environmental materials in the 21st century, and has been widely used in the treatment of industrial wastewater, purification of surface (drinking) water, and smelting and recycling of precious metals.

Graphene purifies the air

With its unique physical and chemical properties, graphene has become the “new darling” in the field of air treatment. The graphene and nano zinc oxide components added to air purification products can degrade harmful substances such as formaldehyde, benzene and TVOC while degrading them, and increase the two major effects of sterilization and deodorization. In short, it can not only produce a complex reaction with organic pollutants, play a good adsorption effect, but also directly kill bacteria.

By combining graphene with a traditional filter material, a graphene oxide-based filter material capable of efficiently removing haze can be prepared. Because the removal of PM2.5 by this filter is purely physical barrier, it is not affected by water vapor and has long-term stability.

The defective graphene skeleton is very thin and has a large number of holes. Therefore, the porous filter membrane assembled by it has staggered internal and horizontal channels, which can ensure that the filter material can effectively retain PM2.5 when the pore diameter is greater than 2.5 microns. At the same time, it guarantees a low breathing resistance of the filter material, and solves the problem that most anti-smoke masks do not breathe.

Graphene purifies heavy metal pollution

Graphene oxide is the material with the largest specific surface area among all carbon nanomaterials. During the preparation of graphene oxide, a large number of active groups such as carboxyl, carbonyl, hydroxyl, and epoxy groups are formed on the surface. Therefore, graphene oxide not only has a sufficiently large specific surface area, but also has a sufficiently high surface function. Group density is an excellent performance adsorbent. Graphene oxide has 10 times as much adsorption capacity as activated carbon. After the surface of graphene oxide is functionalized by special technology, the adsorption characteristics of graphene oxide on metal ions can be further optimized and enhanced.

Heavy metal ion removal ability can reach ppb level

Graphene treats radioactive pollutants

Graphene oxide flakes can quickly adsorb natural and man-made radionuclides and condense into solids; suitable for absorption of terrestrial and underwater radioactive pollution. This is of great significance for the treatment of contaminated waste caused by a nuclear accident.

Graphene oxide has extraordinary adsorption capacity, which can quickly remove radioactive materials in polluted water bodies. Scientists have determined that atomic thickness graphene oxide flakes can quickly adsorb to natural and man-made radionuclides and condense into solids. The flakes are soluble in liquids and can be easily mass-produced. Graphene oxide will solidify within minutes of introducing simulated nuclear waste, rapidly accumulating the most deadly toxin waste, and this process will also span multiple pH values.

Graphene oxide can be added to a solution of a radioactive substance in an ionic state to obtain a solid nuclear substance and incinerate it. During this process, graphene oxide will burn quickly, leaving only massive radioactive material, which is easy to reuse.

2.81 graphene for desalination